Welcome to Guilin HCM Machinery Official WebSite!

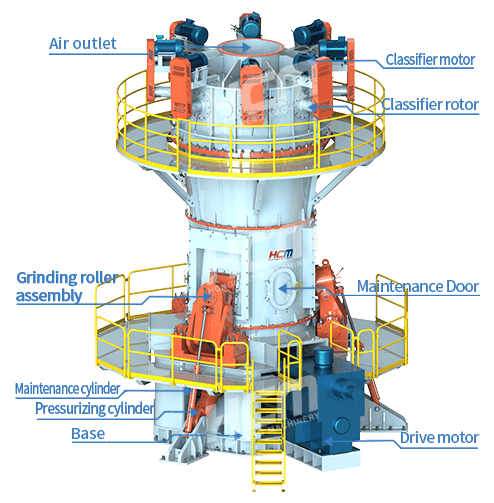

HLM series vertical grinding mill is an advanced energy-saving mill equipment integrating drying, grinding, grading and conveying, developed by Guilin Hongcheng through learning and introducing foreign advanced technology and after more than 20 years of painstaking research and development.

Guilin Hongcheng’s HLM vertical roller mill has the advantages of high grinding efficiency, low power consumption, large feeding particle size, easy adjustment of product fineness, simple equipment process, small footprint, low noise, small dust, easy use and maintenance. It also has the advantages of low operating cost and low consumption of wear-resistant materials.

It solves the problems of low output, high energy consumption and high maintenance cost of ordinary industrial mills. The product performance has reached the international advanced level. It can replace expensive imported vertical mills and meet the needs of large-scale, intelligent and intensive industrial milling.

It can be widely used in electric power, metallurgy, solid waste treatment, cement, chemical industry, non-metallic minerals and other industries. The materials can be ground range from high humidity (20-30% water content) to dry materials (<1%), from difficult to easy-to-grind materials, the product fineness ranges from coarse to fine, and it has rich types in grinding powder.

The single machine has large production capacity and low energy consumption, and can use low-valley electricity. Compared with ball milling, the energy consumption is 40-50% lower.

It adopts PLC automatic control system and can realize remote control, which is easy to operate, easy to maintain and reduce labor costs.

The material stays in the pulverizer for a short time, and the repeated grinding is reduced. The product has a uniform particle shape, a narrow particle size distribution, good fluidity, and strong adaptability. The iron content in the product is very small, and the whiteness and purity are high.

The grinding roller can be pulled out of the machine by hydraulic device, which is convenient for maintenance. The roller sleeve can be turned over to extend the service life of the wear-resistant material, with low wear and tear. The grinding roller and the lining plate of the grinding disc are made of special materials and have a long service life.

The whole system has small vibration and low noise. It adopts the overall sealed negative pressure operation system, and the air box pulse dust removal system, which has no dust overflow, and can basically realize a dust-free workshop.

Direct hot air, the hot air directly contacts the material in the mill, the drying ability is strong, and the moisture content of the feed material can reach up to 15%. No additional dryer is required, saving equipment investment costs and energy consumption costs.

The grinding roller limit device is adopted to avoid the violent vibration of the mill due to material breakage. Adopting a new type of grinding roller sealing device, the sealing is reliable, and there is no need to seal the fan, which further reduces the oxygen content in the mill and has excellent explosion suppression performance.

It integrates crushing, drying, grinding, grading and conveying, with simple process flow, compact structure and small footprint, only 50% of the ball mill. It can be arranged in the open air, with low construction cost and direct investment cost reduction.

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Fineness | Product Moisture | Power(kw) |

| HLM32/2 | 2600 | 85-100 | <10% | R0.08<12% | ≤1% | 800-1120 |

| HLM34/3 | 2800 | 130-160 | 1120-1250< | |||

| HLM42/4 | 3400 | 190-240 | R0.08<14% | 1800-2000 | ||

| HLM44/4 | 3700 | 240-300 | 2500-2800 | |||

| HLM50/4 | 4200 | 320-400 | 3150-3350 | |||

| HLM53/4 | 4500 | 400-500 | 3800-4200 | |||

| HLM56/4 | 4800 | 440-550 | 4200-4500 | |||

| HLM60/4 | 5100 | 550-670 | 5000-5400 | |||

| HLM65/6 | 5600 |

600-730 |

5600-6000 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Product specific surface area | Product Moisture | Power(kw) |

| HLM21/2P | 1700 | 20-30 | ≤2% | 220-360㎡/kg(R0.08≤15%) | ≤1% | 400 |

| HLM26/2P | 2000 | 42-55 | 630 | |||

| HLM32/2P | 2600 | 60-75 | 900 | |||

| HLM34/3P | 2800 | 90-110 | 1400 | |||

| HLM35/3P | 2800 | 130-160 | 2000 | |||

| HLM42/4P | 3400 | 160-200 | 2500 | |||

| HLM44/4P | 3700 | 190-240 | 3000 | |||

| HLM45/4P | 3700 | 240-300 | 3800 | |||

| HLM53/4P | 4500 | 300-380 | 4800 | |||

| HLM56/4P | 4800 | 330-420 | 5300 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Product specific surface area | Product Moisture | Power(kw) |

| HLM32/2c | 2600 | 30-35 | <3% | ≥350㎡/kg | ≤1% | 1400 |

| HLM34/3c | 2800 | 70-80 | 1800 | |||

| HLM42/4c | 3400 | 96-110 | 2500 | |||

| HLM44/4c | 3700 | 130-150 | 3350 | |||

| HLM50/4c | 4200 | 150-170 | 3800 | |||

| HLM53/4c | 4500 | 170-200 | 4500 | |||

| HLM56/4c | 4800 | 200-230 | 5300 | |||

| HLM60/4c | 5100 | 240-270 | 6150 | |||

| HLM65/6c | 5600 | 250-290 | 6450-6700 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Product specific surface area | Product Moisture | Power(kw) |

| HLM32/3S | 2600 | 30-40 | <15% | ≥420㎡/kg | ≤1% | 1400 |

| HLM34/3S | 2800 | 50-60 | 1800 | |||

| HLM42/4S | 3400 | 70-83 | 2500 | |||

| HLM44/4S | 3700 | 90-110 | 3350 | |||

| HLM50/4S | 4200 | 110-140 | 3800 | |||

| HLM53/4S | 4500 | 130-150 | 4500 | |||

| HLM56/4S | 4800 | 150-180 | 5300 | |||

| HLM60/4S | 5100 | 180-200 | 6150 | |||

| HLM65/6S | 5600 | 200-220 | 6450-6700 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Fineness | Product Moisture | Power(kw) |

| HLM17/2M | 1300 | 10-15 | <15% | R0.08=2-12% | ≤1% | 160-185 |

| HLM19/2M | 1500 | 14-22 | 220-250 | |||

| HLM21/2M | 1700 | 20-28 | 315-355 | |||

| HLM26/2M | 2000 | 26-35 | 400-450 | |||

| HLM29/2M | 2400 | 45-56 | 560-630 | |||

| HLM32/3M | 2600 | 56-70 | 800-900 | |||

| HLM34/3M | 2800 | 70-90 | 900-1120 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Fineness | Product Moisture | Power(kw) |

| HLM10/2M | 880 | 3-5 | <15% | R0.08=10-15%(Fineness of pulverized coal for blast furnace pulverized coal injection:200mesh80%passed) | ≤1-6% | 45-55 |

| HLM14/2M | 1100 | 7-10 | 90-110 | |||

| HLM17/2M | 1300 | 13-17 | 160-185 | |||

| HLM19/2M | 1500 | 18-24 | 220-250 | |||

| HLM21/2M | 1700 | 23-30 | 280-315 | |||

| HLM26/2M | 2000 | 29-37 | 355-400 | |||

| HLM29/2M | 2400 | 45-56 | 560-630 | |||

| HLM32/2M | 2600 | 56-70 | 710-800 | |||

| HLM34/3M | 2800 | 70-90 | 900-1120 | |||

| HLM42/4M | 3400 | 110-135 | 1400-1600 | |||

| HLM44/4M | 3700 | 140-170 | 1800-2000 | |||

| HLM50/4M | 4200 | 200-250 | 2500-2800 | |||

| HLM56/4M | 4800 | 260-320 | 3150-3500 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Fineness | Power(kw) |

| HLM14/2X | 1100 | 5-7 | ≤5% | 325mesh(44μm)90%passed | 110-132 |

| HLM17/2X | 1300 | 9-13 | 185-200 | ||

| HLM19/2X | 1500 | 15-20 | 250-280 | ||

| HLM21/2X | 1700 | 24-32 | 355-400 | ||

| HLM26/2X | 2000 | 26-35 | 450-500 | ||

| HLM29/2X | 2400 | 36-45 | 560-630 | ||

| HLM32/2X | 2600 | 45-58 | 710-800 | ||

| HLM34/2X | 2800 | 56-80 | 1120-1250 |

| Model | Diameter of grinding table(mm) | Capacity(t/h) | Raw material moisture | Fineness | Product Moisture | Power(kw) |

| HLM21/3X | 1700 | 20-25 | ≤15% | 100mesh(150μm)90%passed | ≤3% | 400 |

| HLM26/3X | 2000 | 25-31 | 560 | |||

| HLM29/3X | 2400 | 42-52 | 710-800 | |||

| HLM32/3X | 2600 | 52-70 | 900-1120 | |||

| HLM34/3X | 2800 | 70-82 | 1120-1250 | |||

| HLM42/4X | 3400 | 100-120 | 1800-2000 | |||

| HLM44/4X | 3700 | 140-160 | 2500-2000 | |||

| HLM50/4X | 4200 | 170-190 | 3150-3350 |

The motor drives the reducer to drive the grinding disc to rotate, and the material is fed into the center of the rotating grinding disc by the air-locking feeding equipment. Under the action of centrifugal force, the material enters the grinding channel, and the grinding rod is continuously rotated and rolled, so the material is squeezed, ground and sheared.

At the same time, the hot air is sprayed upwards evenly at a high speed from the air ring surrounding the grinding disc. The pulverized materials are blown up and dried, and enter the classifier with the wind. The qualified fine powder passes smoothly and is collected by the dust collection equipment. The unqualified coarse powder falls back to the grinding table under the action of the classifier blade, and is re-ground together with the newly fed material.