Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-05-29 15:19:28

Global sand shortage, sand prices rise

In the latter half of 2018, the price of sand and stone in some places has increased by nearly 1000%. Making sand from ceramic tile waste can not only meet the standard of construction sand, but also become the "savior" of sand and stone shortage.

The amount of sand and stone that can be seen everywhere has increased 10 times in 10 years, and the UAE has spent $456 million a year to import sand and stone. In the face of the shortage of sand and stone resources, how should China deal with the infrastructure maniac? Making sand with ceramic tile waste is a feasible project.

Is there a market for ceramic tile waste sand making? What is the quality of being a replacement for sand and stone?

As the leftover materials of the construction industry, ceramic tile waste is often discarded in the corner. The occupation of land, not to mention, also causes a lot of waste of resources. Using tile waste to make sand, according to the calculation of cheap artificial sand and stone, if you start 10 hours a day, you can earn nearly one million a day, and its profit value is high.

And ceramic tile waste sand in ceramic tile waste recycling is not a new thing! Tile waste sand used in steel casting, easy to take off film, casting smooth. Making sand and leather with ceramic tile waste can reduce labor intensity and increase economic benefit.

What kind of equipment is used for making sand from tile waste? How about the price?

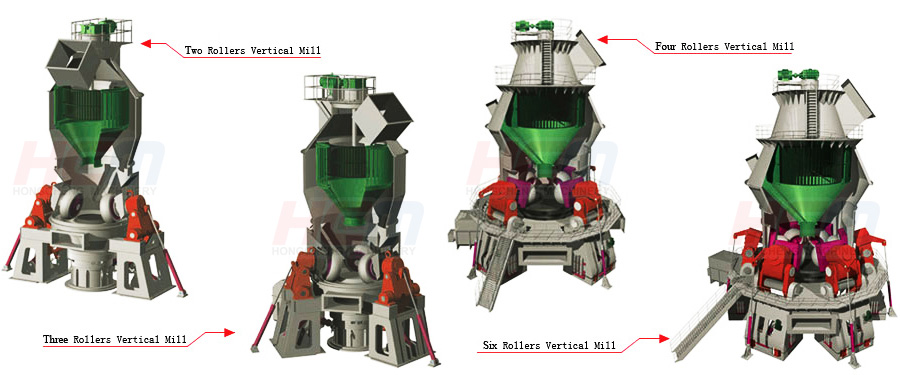

So, what kind of equipment should be used to make sand from tile waste? What is the price of the equipment? Ceramic tile waste sand by processing different specifications and sizes of ceramic tile waste to meet the daily needs of gravel. HCM production of vertical mill after more than 20 years of dedicated research. It is a set of crushing, drying, grinding, grading, transportation as one of the efficient energy-saving advanced equipment.

HLM vertical mill has various advantages in making sand from tile waste. For example, it has the advantages of high grinding efficiency, low power consumption, large feed particle size and easy to adjust product fineness.

Guilin Hongcheng mineral powder mill - HLM vertical roller mill

〖Product fineness〗:22-180μm

〖Production capacity〗:5-700t/h

〖Grinding filed〗:It aims at all kinds of non-metallic mineral materials with Mohs hardness less than 7 and humidity less than 6%. The grinding mill is widely used in electric power, metallurgy, cement, chemical industry, rubber, paint, ink, food, medicine and other production fields.

〖Performance characteristic〗:It integrates drying, grinding, grading and conveying. It has the characteristics of high grinding efficiency, low power consumption, large feed particle size, easy to adjust product fineness, simple equipment process, small floor area, low noise, small dust, simple operation and maintenance, low operation cost, less consumption of wear-resistant materials, etc.

HCMilling(Guilin Hongcheng) is a professional R & D and manufacturer of ore mill equipment. The new Raymond mill, ultra-fine mill, vertical roller mill, super-fine vertical grinding mill and other equipment have high grinding efficiency and greater production capacity.

If you are interested in calcium silicon slag grinding mill for papermaking, pls contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.