Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-05-31 14:00:57

With the continuous increase of stone consumption, improper stacking of stone waste will damage the environment, and it has to pay an economic price to discard as waste. How to make full use of these stone wastes and turn them into treasure has become a headache.

The cause of stone waste

Due to the different specifications of stone purchased by users, a large number of stone wastes are discarded in the process of stone mining, processing and use. Many enterprises let these wastes discharge and accumulate, which has caused environmental pollution and ecological damage, and some even caused conflicts with the surrounding society. The comprehensive utilization of stone powder and leftover materials in stone waste residue through crushing, grinding and other reprocessing can increase the income of enterprises and protect the environment from being damaged.

Grinding and sand making equipment for HCM production

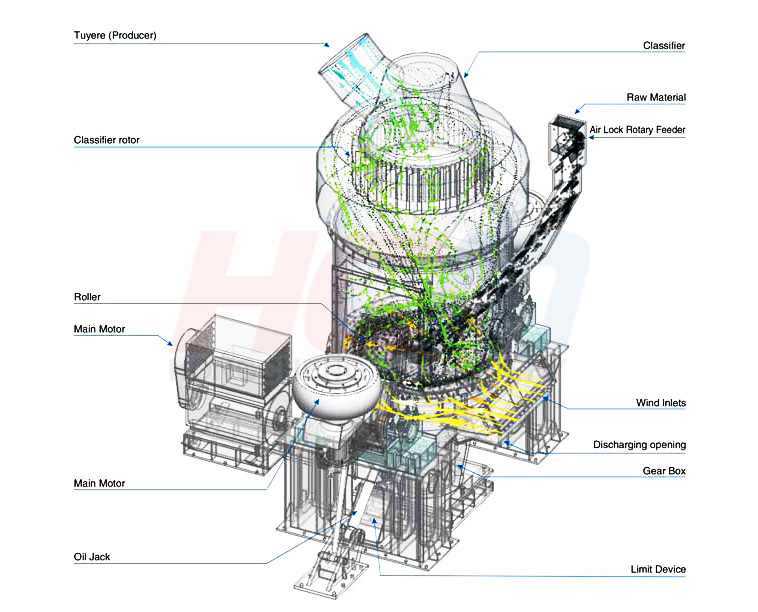

Vertical roller mill is a very suitable equipment for stone waste treatment and processing. The equipment has six functions of crushing, drying, grinding, grading and conveying. The crushing process can be completed at one time. And it can grind materials with humidity below 15%, and the particle size of finished products is 22-180 μ M can be randomly allocated to meet the actual production needs of customers.

Guilin Hongcheng mineral powder mill - HLM vertical roller mill

〖Product fineness〗:22-180μm

〖Production capacity〗:5-700t/h

〖Grinding filed〗:It aims at all kinds of non-metallic mineral materials with Mohs hardness less than 7 and humidity less than 6%. The grinding mill is widely used in electric power, metallurgy, cement, chemical industry, rubber, paint, ink, food, medicine and other production fields.

〖Performance characteristic〗:It integrates drying, grinding, grading and conveying. It has the characteristics of high grinding efficiency, low power consumption, large feed particle size, easy to adjust product fineness, simple equipment process, small floor area, low noise, small dust, simple operation and maintenance, low operation cost, less consumption of wear-resistant materials, etc.

Application of crushed stone residue

After crushing, the stone residue is converted into recycled orthopedics to replace natural sand for concrete or road construction cushion. After crushing the stone waste residue, the remaining waste residue can be sorted and used to fill the pit to provide nutrients for plants.

Making the best use of stone waste can not only increase economic benefits, but also save energy and protect the environment. It has been a key project supported by the government, and there are unlimited prospects for the design and reuse of stone waste in many places.

HLM vertical roller mill has various advantages in making sand from tile waste. For example, it has the advantages of high grinding efficiency, low power consumption, large feed particle size and easy to adjust product fineness. HCMilling(Guilin Hongcheng) is a professional R & D and manufacturer of ore mill equipment. The new Raymond mill, ultra-fine mill, vertical roller mill, super-fine vertical grinding mill and other equipment have high grinding efficiency and greater production capacity.

If you are interested in calcium silicon slag grinding mill for papermaking, pls contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.