Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-10-21 16:51:47

The operation specification and process of HCM vertical mill have become the concern of more and more people in the market, because HCM vertical mill introduces foreign advanced technology. After more than 20 years of painstaking research and development, it has developed a high-efficiency and energy-saving advanced equipment integrating crushing, drying, grinding, grading and transportation. It is widely welcomed in the industry because of its high grinding efficiency, low power consumption, large feed particle size, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise and less dust. The specific HLM vertical roller mill operation specification and process description are as follows:

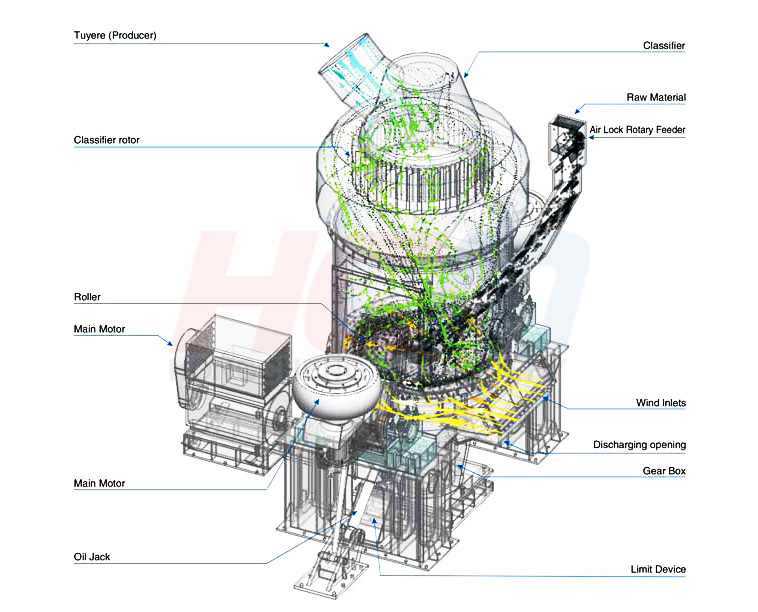

Working principle of HCM vertical roller mill

The motor drives the reducer to drive the grinding disc to rotate, and the materials to be ground are sent to the center of the rotating grinding disc by the air lock feeding equipment. Under the action of centrifugal force, the material moves around the grinding plate and enters the grinding roller table. Under the pressure of the grinding roller, the material is crushed by extrusion, grinding and shearing. At the same time, the hot air is sprayed upward evenly at high speed from the air ring around the grinding disc, and the ground material is blown up by the high-speed air flow at the air ring. On the one hand, blow the materials with coarse particle size back to the grinding plate for re grinding, on the other hand, dry the suspended materials, and the fine powder is brought into the classification machine by hot air for classification. The qualified fine powder flows out of the mill with the gas and is collected by the dust collection equipment as the product. The unqualified coarse powder falls back to the grinding plate under the action of the blades of the grading machine and is re ground together with the newly fed materials. In this way, the whole process of grinding operation is completed.

HLM vertical roller mill operation specification

In order to ensure the normal operation of the vertical mill, we need to master the basic HCM vertical grinding mill operation specifications to ensure that each product can reach a fixed production capacity.

1.Wear labor protection articles.

2.Two people are required to walk together for the maintenance of the vertical mill, keep in touch with the central control at all times, and leave special personnel outside the mill for safety supervision.

3.Low voltage lighting must be used before entering the vertical mill.

4.Before entering the vertical mill, cut off the power supply of the main motor, exhaust fan, feeding equipment and powder concentrator of the vertical mill, and turn the on-site control box to the "maintenance" position.

5.When replacing the grinding roller liner and components, pay attention to prevent collision and injury, and take safety protection measures.

6.When working at height, the operator shall first ensure that the tools are intact and neat, and fasten the safety belt at the same time.

7. When the mill must be inspected during the operation of the kiln, safety precautions shall be taken, close contact shall be maintained with the central control, special personnel shall be arranged to take charge of the safety work, at the same time, the exhaust of the high-temperature fan at the kiln tail shall be increased, the hot air baffle at the inlet of the mill shall be closed and powered off, and the negative pressure of the system shall be stable;

8. When it is confirmed that the mill body has been fully cooled, the ash deposition depth and temperature of the mill shall be verified. If the mill is overheated, not vented and too much ash is accumulated, it is strictly prohibited to enter the mill. At the same time, attention must be paid to whether there is material accumulation in the feed chute to prevent slipping and wounding people.

9. Handle the power failure procedures according to relevant regulations.

With the continuous improvement of powder market, HLM vertical mill has become a hot separation equipment for many customers. HLM vertical mill operation specification and process safety have also become a factor considered by many customers to ensure the production safety of vertical mill. After installation, the company will train customers to carry out formal vertical mill operation specifications and process training, so that customers' products can be produced online at the fastest speed.