Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-11-16 17:16:57

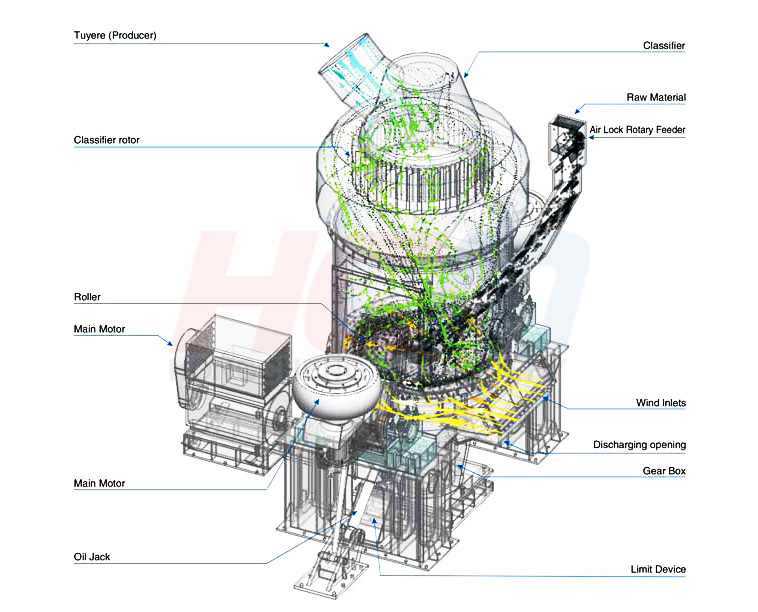

The HLM vertical roller mill produced by HCMilling(Guilin Hongcheng) is preferred as the biochar grinding mill equipment, which has high grinding efficiency, low power consumption, large feed particle size and easy adjustment of product fineness. The equipment has simple process flow, small floor area, low noise and low dust. It has been deeply cultivated in the grinding field for 30 years, and is deeply welcomed by the market and industry. How much does it cost to invest in a biochar crushing production line?

(1).jpg)

The HLM vertical roller mill produced by HCMilling(Guilin Hongcheng) is preferred as the biochar crushing equipment, which has high grinding efficiency, low power consumption, large feed particle size and easy adjustment of product fineness. The equipment has simple process flow, small floor area, low noise and low dust. It has been deeply cultivated in the grinding field for 30 years, and is deeply welcomed by the market and industry. How much does it cost to invest in a biochar crushing production line?

On site display of HCM biochar crushing vertical roller mill ----------- with parameters

|

Model |

Pitch diameter of grinding disc (mm) |

Capacity(t/h) |

Raw material moisture |

Pulverized coal fineness |

Power of motor(kw) |

|

HLM10/2M |

800 |

3-5 |

<15% |

R0.08=10%-15% |

45/55 |

|

HLM14/2M |

1100 |

7-10 |

<15% |

90/110 |

|

|

HLM16/2M |

1250 |

9-12 |

<15% |

110/132 |

|

|

HLM17/2M |

1300 |

13-17 |

<15% |

160/185 |

|

|

HLM18/2M |

1300 |

14-19 |

<15% |

185/250 |

|

|

HLM19/2M |

1400 |

18-24 |

<15% |

220/250 |

|

|

HLM21/2M |

1700 |

23-30 |

<15% |

280/315 |

|

|

HLM24/2M |

1900 |

29-37 |

<15% |

355/400 |

Note: Harding grindability coefficient of raw coal 50~70

Main advantages of HCM biochar crushing vertical roller mill

【Capacity】1-200t/h

【Fineness】22-180μm

1、Low investment: it integrates crushing, drying, grinding, grading and transportation. Simple process flow, less system equipment and low comprehensive investment cost.

2、High reliability: it adopts grinding roller limit device, which makes the sealing more reliable.

3. High degree of automation: it can realize remote control, simple operation, convenient maintenance and reduce labor cost.

4. High grinding efficiency: large production capacity of single machine.

5. The equipment is more environmentally friendly: the system has small vibration, low noise and full negative pressure operation. It is a new energy-saving technology strongly advocated.

6. Strong drying capacity: it can directly pass hot air, strong drying capacity, and the feed moisture is as high as 15%.

The adsorption capacity of biochar was enhanced after crushing

(1) Physical or surface adsorption is to remove heavy metals by diffusion of metal ions into the adsorbent pores without forming chemical bonds. Biochar with high specific surface area and pore volume has strong affinity for metals. Therefore, metal ions are physically adsorbed on the carbon surface and retained in the pores.

(2) Activated carbon with high specific surface area is a porous and potential carbonaceous adsorption material. This material has highly developed internal pore structure and huge specific surface area. Therefore, it has strong adsorption. It is an excellent adsorbent.

The price of investing in a biochar crushing production line

How much does it cost to invest in a biochar grinding mill production line? The specific equipment quotation also needs to be customized in combination with the specific type selection scheme. HCMilling(Guilin Hongcheng) is committed to providing non-metallic ore grinding services, fearless of environmental impact assessment, and technical engineering to provide you with professional services one-on-one.

If you are in need of any non-metallic grinding mill, contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.