Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2021-11-18 14:35:23

HCMilling(Guilin Hongcheng)as a benchmark enterprise for powder equipment manufacturing in China, it produces mineral powder vertical roller mill, which are used in cement raw clinker, electric power, metallurgy, chemical industry and other fields. The vertical roller mill of mineral powder has been running well since it was put into operation, and has been highly praised by customers. However, recently, some customers have come to consult about the reasons why there are many returns of vertical mill of mineral powder? Through our HCM professional sales engineers to give answers and solve problems.

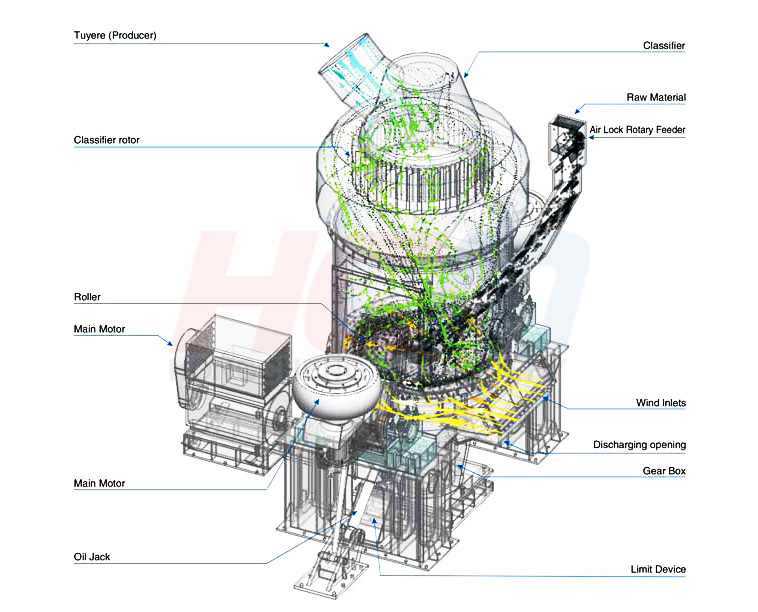

Working principle of mineral powder vertical grinding screen

After drying and grinding, the slag is sucked into the powder concentrator from the grinding plate under the action of wind force in the mill. The stationary blade installed on the powder concentrator will guide the dusty air from the ascending air flow to the tangential air flow, and the rotation direction of the rotor (moving blade) is consistent with the tangential air flow. There is centrifugal force in the gap between the stationary blade and the moving blade, and the dust is screened in this area. Larger particles are thrown out and fall into the silo under the action of gravity and sent back to the vertical mill for reprocessing. The finished product enters the outlet of the upper shell of the powder concentrator with the air flow through the rotor and leaves the powder concentrator.

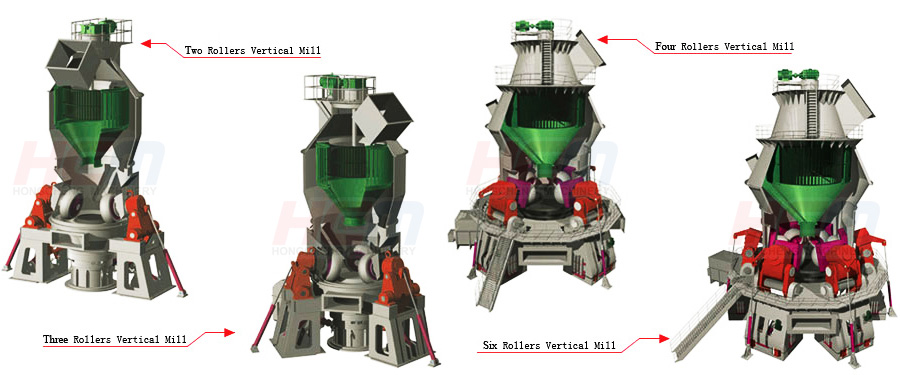

HLM vertical roller mill

〖Fineness〗:22-180μm

〖Capacity〗:5-700t/h

〖Grinding field〗:It is aimed at various non-metallic mineral materials with Mohs hardness below grade 7 and humidity within 6%. The mill is widely used in power, metallurgy, cement, chemical industry, rubber, coating, ink, food, medicine and other production fields.

〖Performance characteristics〗:It integrates drying, grinding, grading and transportation. It has the characteristics of high grinding efficiency, low power consumption, large feed particle size, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise, low dust, simple use and maintenance, low operation cost and low consumption of wear-resistant materials.

Causes and Countermeasures of excessive return material of vertical grinding of mineral powder

(1)The fineness of the grinding powder depends on the adjustment of the static blade direction and rotor speed of the powder concentrator. If the stationary blade is adjusted outward (greater tangential force) and the rotor speed is increased, finer mineral powder will be produced; On the contrary, coarse mineral powder will be produced. If the outward adjustment of the stationary blade is too large and the production of mineral powder is fine, there will be too much material returned from the vertical grinding of mineral powder, so stop the machine and adjust the stationary blade internally for test run.

(2)Adjust the speed of the rotor when the air volume and air pressure of the system are stable. If the rotor speed is too fast, the finer the fineness of the finished material is, so there is more material returned from the vertical grinding of mineral powder.

(3)When the parameters are stable, if the rotor speed is adjusted, the fineness of mineral powder has no obvious change. The wear of the upper concentrator is the main reason for the large amount of returned materials of the vertical grinding of mineral powder, and the unstable operation of the central control system is the secondary reason. Focus on the inspection and repair of the counter mill concentrator. The seriously worn stationary blade can be overhauled or the reinforcing bar can be repaired.

HCM equipment is easy to maintain

To sum up, we basically understand the specific reasons for the large amount of recycled materials in the vertical grinding of mineral powder. If one equipment fails and is repaired continuously, it will lead to shutdown and shutdown, and the maintenance cost of the enterprise is high. If you choose the mineral ore vertical mill produced by HCMilling (Guilin Hongcheng), it has convenient maintenance and low operation cost. The grinding roller can be turned out of the machine with hydraulic device, and there is a large maintenance space for replacing the roller sleeve liner and the mill. HCM equipment adopts wear-resistant materials with long service life, which directly improves the competitive strength of the enterprise.

If you are in need of any non-metallic grinding mill, contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.