Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2022-05-26 14:35:38

Grain slag is a granulated foam-shaped slag formed by rapid cooling of blast furnace slag with water in a high temperature molten state. Its texture is light and brittle, and it is easy to grind into powder. Replacing one ton of Portland cement by the same amount will reduce carbon emissions by 0.77 tons, and the combined emissions will be less than 10% of cement. Due to its low cost and high performance, slag micropowder has brought considerable economic benefits to customers. The backbone behind it is HCMilling(Guilin Hongcheng)'s grain slag grinding mill equipment - HLM grain slag vertical roller mill.

News broadcast

Recently, the grain slag micropowder preparation production line built by HCMilling(Guilin Hongcheng) has been installed! The main equipment of this production line is HLM series grain slag vertical roller mill, which is designed and constructed by HCMilling(Guilin Hongcheng) according to local conditions and rational planning. This production line has scientific and reasonable design, compact layout, intelligent and environmental protection, and truly makes customers feel the economic benefits brought by new energy-efficient equipment and new technologies!

Project Overview:

Processing material: grain slag

Finished particle size: 420㎡/kg

Single production capacity: 50±5t/h

Equipment used: HLM2800 vertical roller mill

Finished product use: cement mixture

1.jpg)

(1).jpg)

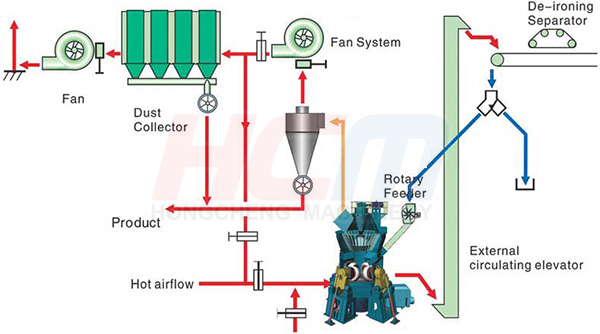

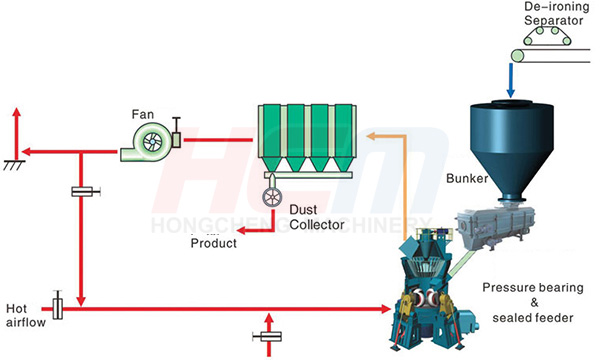

Pulverizing process of grain slag vertical roller mill

The first stage: drying of raw materials

After the grain slag is dried and the humidity is within 15%, it can reach the moisture requirement of the material that can enter the mill.

Stage 2: Grinding

The dried grain slag is sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

Stage 3: Grading

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.

Stage 4: Collection of Finished Products

The powder that meets the fineness enters the dust collector with the air flow through the pipeline for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then uniformly packed by a powder tanker or an automatic baler.

▲HLM vertical mill production process flow chart

Technical advantages:

1. Integrated design, one machine for multiple purposes

It integrates crushing, drying, grinding, grading and conveying, with compact layout and small footprint; it can be applied to the grinding of non-metallic ores, pulverized coal, slag, raw cement, clinker, etc.

2. High grinding efficiency and good discharge quality

It adopts special structure design of grinding roller and grinding disc. The grinding roller adopts hydraulic automatic pressure device, which has a larger grinding area and high grinding efficiency;

3. Easy maintenance and high degree of automation

It adopts PLC automatic control system, which can realize remote control, reduce the workload of staff, improve work efficiency and reduce maintenance costs.

4. Strong drying ability, energy saving and environmental protection

The vertical roller mill can be directly ventilated with hot air, and the hot air directly contacts the material in the mill. The drying capacity is strong, and the moisture content of the feed material can reach up to 15%. The whole system has small vibration and low noise. The whole system is sealed and operated under full negative pressure, and there is no dust spillage. Basically, a dust-free workshop can be realized.

The strength of HCM

HCM Group originated in 1991. After more than 30 years of steady development, HCMilling(Guilin Hongcheng) has been certified as a national high-tech enterprise. In the powder equipment manufacturing industry, the market sales are in the forefront. For many years, HCMilling(Guilin Hongcheng) has been benchmarking against international standards, and its series of products have passed ISO9001:2015 quality management system certification, EU CE certification, etc. More and more customers at home and abroad benefit from the equipment with high technology content, high reliability and low maintenance cost.

If you need grain slag grinding mill, you can consult online, and our sales engineers will provide you with one-to-one service. Please contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.