Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2022-11-30 20:19:11

Vanadium titanium slag vertical roller mill is an advanced equipment for grinding vanadium titanium slag. Vanadium titanium slag vertical roller mill is an effective means to improve the activity of vanadium titanium slag. As the manufacturer of vanadium titanium slag vertical roller mill, HCMilling(Guilin Hongcheng) will introduce the application of low active vanadium titanium slag in building materials and the vanadium titanium slag grinding mill technology of vertical roller mill for vanadium titanium slag.

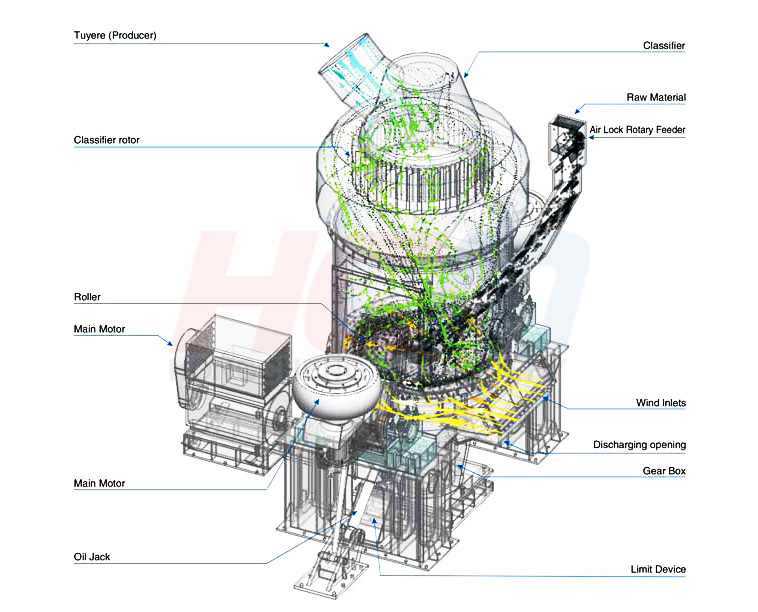

HLM series vanadium titanium slag vertical roller mill

The TiO2 content of vanadium titanium slag discharged in China is mostly 16%~25%, but there are also some vanadium titanium slag with TiO2 content less than 10%, and titanium minerals are dispersed in the slag, which is difficult to separate. Therefore, the comprehensive utilization of titanium bearing blast furnace slag is difficult. In order to utilize the resource of titanium bearing blast furnace slag, China has started comprehensive utilization research since the 1960s. Several typical utilization methods of low active vanadium titanium slag in building materials are summarized as follows:

1. Used as cement admixture: Vanadium titanium slag, steel slag, ordinary blast furnace water quenched slag and cement clinker can be finely ground in a certain proportion to produce a composite cement with a strength grade of 52.5. The test results show that with appropriate process technology and formula, the cement clinker has a high content of C3S and C3A. When the cement clinker content is 45% and the vanadium titanium slag content is 46%, under the action of activator and additive, the 28d flexural strength of cement is 8.8 MPa, the compressive strength is 48.5 MPa, the sulfate resistance coefficient is more than 1.0, the dry shrinkage is less than 0.1%, and the wear coefficient in the wear resistance index is less than 3.03 kg/m2, meeting the requirements of the national standard for road cement, And meet or exceed foreign road cement standards.

2. Use as concrete aggregate: although the activity of vanadium titanium slag is lower than that of ordinary blast furnace slag, vanadium titanium slag can be used as a component to prepare concrete because it contains no harmful components that affect cement hydration. The crushing index of vanadium titanium slag has little relationship with the compressive strength, apparent density, bulk density and porosity. The crushing index fluctuates slightly and falls within the scope of crushed stone crushing index I. It does not contain free CaO, is autoclaved for many times without pulverization and cracking, has good stability, low sulfur content, and has no iron manganese decomposition trend, and the high titanium heavy slag stacked in the open slag yard for a long time is very stable, without cracking, pulverization or other decomposition phenomena, has the mechanical strength of class 2~3 stone, and the wear resistance is no less than limestone, and can be used as the coarse and fine aggregate of concrete.

3. As building blocks or bricks: MU10 slag bricks can be produced with high titanium blast furnace slag as the main raw material and steam curing process. On the basis of meeting relevant national standards, the slag content in slag bricks is more than 80%. Panzhihua Iron and Steel Group Co., Ltd. has developed a non fired building brick with strength grade of MU10, using high titanium blast furnace water quenched slag as aggregate and fly ash and lime as cementitious materials, which can be used for walls and foundations of general industrial and civil buildings.

The grinding technology of vanadium titanium slag grinding mill plays an important role in the equipment application of low active vanadium titanium slag in building materials: at present, scholars have used vanadium titanium slag for cement production and concrete engineering after grinding, and the grinding fineness is about 400~500m2/kg, mostly used in combination with fly ash, steel slag, limestone, or by adding an appropriate amount of activator to stimulate the potential hydraulic properties of vanadium titanium slag, As an additive alone, its activity index can only reach the S75 level, and the content is generally low, which limits its large-scale application in the building materials industry. Due to the existence of difficult to grind phases in slag, the comprehensive power consumption in the process of superfine powder grinding is too high, so it is urgent to provide an efficient preparation method of vanadium titanium slag superfine powder admixture.

The vanadium titanium slag grinding mill technology of HCMilling(Guilin Hongcheng)’s HLM series vanadium titanium slag vertical roller mill can obtain more than 700 ultra-fine powders with high specific surface area, greatly improve the hydration activity of vanadium titanium slag, the greater the contribution to cement strength, the higher the grinding efficiency, and realize its efficient resource utilization in cement and concrete. If you have relevant requirements, please contact mkt@hcmilling.com or call at +86-773-3568321, HCM will tailor for you the most suitable grinding mill program based on your needs, more details please check www.hcmilling.com.