Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-11-27 16:31:58

Hcmilling (Guilin Hongcheng) offers a wide spectrum of Vertical grinding mill solutions that can be used in grinding slag, coal, cement, lime,etc., for power plant desulfurization, non-metallic minerals and other milling fields. In this paper we will discuss about the differences between vertical grinding mill and ball mill.

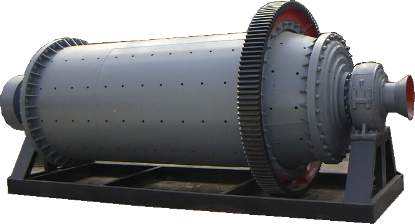

Vertical grinding mill is mainly used for fine powder processing of non-flammable and explosive brittle materials with Mohs hardness under 7 and moisture under 6%. Vertical mill is a material bed crushing grinding equipment. Ball mill is to re-crush material after material have been crushed.

1. Ball mills has lower utilization of energy consumption, and there is an obvious tendency to be replaced by vertical grinding mill. While ball mills have a particle shape that is approximately spherical, which is conducive to raw material calcination and cement hydration and hardening" This unique feature makes most clinker mills still use ball mills.

2. Thanks to the scientific grinding method of vertical grinding mill, grinding power has completely been utilized by materials with timely classification, short dwell time of the material to be ground ensures superior quality and efficient grinding, powder consumption reduced by up to 20% compare with ball mill.

3. The vertical mill allows a larger amount of wind to pass, so the drying capacity is larger; material in the mill is in a suspended state, which increases the contact area between the material and the air flow, the excellent heat exchange conditions endures efficient drying. But for the ball mill, when grinding high moisture materials, it is very necessary to install extra drying equipment in front of the ball mill due to its limited air flow through the ball mill.

4. The space occupied by the vertical mill is only 50% ~ 70% of the ball mill, and the physical space occupied is smaller.

5. Lower initial installation cost. The initial installation, running and maintenance cost of the vertical grinding mill are only 70% ~ 80% of the ball grinding mill.

6. Larger size of grinding material, which can generally reach 3% -5% of the diameter of the grinding roller, large scare grinding mill allows a large feed size which can save secondary crushing. While ball mill can only feed smaller size materials as it is limited by its larger steel ball diameter.

7. For vertical grinding mill like HLMX Superfine Grinding Mill, fineness is easy to adjust, particle distribution is evenly, and chemical composition is stable. (The ratio of fine powders produced by ball mills is lower.)

8. Vertical grinding mill has less dust or noise pollution since there is a good sealing pipe system and no collision between the grinding rollers and the liners. Moreover, the mill operates under negative pressure conditions, minimizing mill maintenance and plant housekeeping while maximizing the service life of major mechanical components.

9. The vertical mill has a short conversion time, which can convert different raw materials on the same mill in a very short time to produce different products. While the ball mills are opposite.

10. Lower abrasion of vertical grinding mill. There is no direct contact between metals during operation, so the metal consumption is a bit, the accessories have less wear and long life, and the metal wear per unit product is generally 5-10 grams / ton. While the ball mill uses collision friction in high wear.

11. HLM Vertical Roller Mill has a more simpler process, the mill can grind, dry, and classify which saves foot print, ensures lower rate of breakdowns, and saving the capital cost.

12. Vertical grinding mill has expensive wear parts, but compare with ball mill’s whole maintenance of mill, lifter, and classifier, it is stiller cheaper and simpler than ball mill.

The above are the main differences between vertical mills and ball mills. When choosing the milling equipment, the grinding material and capacity should be considered. Hcmilling (Guilin Hongcheng) experts will assist you in creating an efficient vertical grinding mill model selection to ensure you get your desired grinding effect.