Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-11-29 17:00:50

What is Limestone?

limestone is mainly composed of calcium carbonate (CaCO3). Lime and limestone are widely used as construction materials and industrial raw materials. Limestone can be directly processed into building stone material and fired into quicklime, quicklime absorbs moisture or adds water to become slaked lime, main component is Ca (OH) 2. The slaked lime can be processed into lime slurry, lime paste, etc., and used as a coating material and tile adhesive. Calcium carbonate is mainly composed of limestone, which is the main raw material for glass. Calcium carbonate can be directly processed into building stones or fired into quicklime. Lime is divided into quicklime and slaked lime. The main component of quicklime is CaO, which is generally in massive and pure white, and light gray or light yellow if it contains impurities.

Quicklime absorbs moisture or adds water to become hydrated lime, which is also known as slaked lime. Its main component is Ca (OH) 2. The slaked lime can be processed into lime slurry, lime cream, lime mortar, etc., and used as coating material and tile adhesive. Cement is calcined by mixed limestone and clay at high temperature.

The applications of Limestone

1.200 mesh D95Limestone can be processed by a limestone grinding mill into limestone powder which is divided into the following types according to different fineness.

It is used to produce anhydrous calcium chloride, and is the auxiliary raw material for the production of sodium dichromate, it is the main raw material for glass and cement production, and can be used in building materials and poultry feed.

2.325 mesh D99

It is a raw material for producing anhydrous calcium chloride and glass, white filler for rubber and paint, and building materials.

3.325mesh D99.9

Used as a filler for plastics, paint putties, paints, plywood and paint.

4.400 mesh D99.95

Used as filler for electric wire insulation, rubber molded products and filler for asphalt linoleum.

5. Power plant desulfurization:

Used as desulfurization absorbent for flue gas desulfurization in power plant.

Limestone milling process

Currently the Maximum amount consumed of limestone powder is for power plants desulfurization.

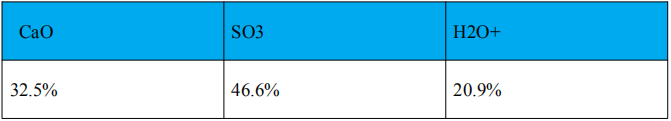

Limestone raw material composition analysis

Note: Limestone has obvious diversities from different places, especially if the content of SiO2 and Al2O3 is high, it is more difficult to grind.

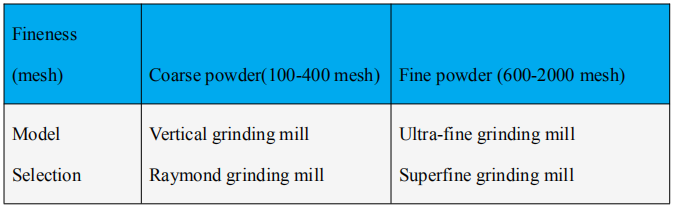

2. Select limestone grinding mill based on the capacity and fineness requirements;1. Product power consumption per ton of system : 18 ~ 25kWh / t. There are differences according to raw material and product requirements;

3. Main applications: power desulfurization, blast furnace smelting solvents, etc.

Phase 1: Crushing the raw materials

limestone blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 2: Grinding

The crushed coarse limestone are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

Analysis of different types of grinding mill

HC series Large-scale Pendulum Grinding Mill

It is used for grinding coarse powder below 600 mesh, featuring low capital investment, reduced energy consumption.

HLMX Series Super Fine Vertical Grinding Mill

Large-scale equipment and high throughput rate, strong stability is high. Disadvantages: high equipment investment costs.

Superior ultra-fine powder, lower energy consumption, reduced equipment investment cost. This mill has a good The market prospect. Disadvantage: lower throughput rate.

Limestone powder Case

A power plant of a calcium industry group production of a 150,000 t / annual

model type and quantity: 2 sets of HC1700

Grinding Materials: Limestone

Fineness: 325mesh D96

Capacity: 10t / h

The Calcium Industry Group is a large-scale metallurgical ash production enterprise which is the supplier of metallurgical raw materials for many large and medium-sized enterprises and limestone production reaches one million. It has purchased 2 sets of HC1700 pendulum grinding mill, and 2 sets of 4R Raymond roller mills since 2010 from Guilin HongCheng Mining Equipment Manufacture Co., Ltd. The mill equipment has been operating stably so far and created large economic benefits to the owners.