Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-12-03 13:47:30

What is marble?

Marble is a metamorphic rock formed by raw gemstone under the effects of high temperature and pressure in the crust, it can be ground into fine powder by marble grinding mill. The main component of marble is calcium carbonate, which accounts for more than 50%, mainly composed of calcite, limestone, serpentine and dolomite. Marble’s Mohs hardness is between 2.5-5, it is in different colors and with obvious patterns, it contains impurities and many mineral particles. Its physical properties of are relatively softer than granite, stronger compressive strength and good physical and chemical properties, and it plays a very important role in our daily life.

Applications of Marble

Marble texture is soft, beautiful, solemn, and elegant, it mainly to be processed into various shapes and plates for building walls, floors, platforms, and columns. It is also used in monumental buildings such as monuments, towers, statues, etc. It is an ideal material for decorating luxurious buildings; it a traditional material for sculpture that can be sculptured into artworks such as arts and crafts, stationery, lamps, utensils, etc. Besides, the crushed marble that produced during mining are also commonly used in making artificial stone, terrazzo, stone rice, stone powder, and can be used as fillers in coatings, plastics, rubber and other industries.

Mable Milling Process

Mable raw material composition analysis

|

CaCO3 |

MeCO3、 CaO、MnO、SiO2, etc. |

|

50% |

50% |

Model Selection of Marble Grinding Machine

|

Fineness (mesh) |

Fine(20mesh-400mesh) |

Superfine(600mesh-2000mesh) |

|

Model Selection |

Vertical grinding mill Vertical pendulum grinding mill |

Superfine grinding mill Ultra-fine grinding mill

|

Note: 1. Select the main mill according to the capacity and fineness requirements.

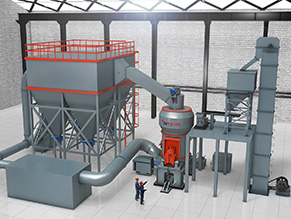

Phase 1: Crushing the raw materials

Marble blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 2: Grinding

The crushed coarse marble are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine marble powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

Analysis of different types of grinding mill

Low investment cost, high throughput rate, lower energy consumption, stable equipment performance and lower noise; it is a good option for marble fine powder processing, while the scale is smaller than vertical grinding mill.

HLM Series Vertical Grinding Mill

Large-scale equipment, high throughput rate, final product in high degree of spheroidization, superior quality, while the cost is expensive.

HLMX Series Superfine Vertical Grinding Mill

It is the optimal choice for 600 mesh superfine large scale production, or those who have high product demand of high degree of spheroidization.

HCH Ultra-fine Grinding Mill

It can be used to grinding superfine powder between 600-2500 mesh, lower investment cost, lower energy consumption.

Marble Powder Grinding Case

Model type and quantity: 2 Sets of HCH1395 Vertical Grinding Mill

Grinding Materials: Marble

Fineness: 800mesh D97

Capacity: 6-8t/h

Customer Evaluation: Hcmilling (Guilin Hongcheng)’s marble grinding mill with efficient grinding, advanced milling technology, stable operation, reliable safety performance, environmental protection and energy saving, excellent quality of final products.

Since Hongcheng Marble Mill was officially put into this processing production line, our milling efficiency has been greatly improvement, the product feedback is welcomed. We are very satisfied with this reliable product quality and considerate service.