Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-12-05 14:21:08

What is Bentonite?

Bentonite a non-metallic mineral with 85~90% montmorillonite, and a small amount of illite, kaolinite and halloysite, etc. It typically in white or light yellow,sometimes with light red, light green, etc., which mainly determined by the iron content. The property of bentonite is mainly determined by montmorillonite. Bentonite grinding mill is necessary for powder production. According to the type, content and interlayer charge of montmorillonite exchangeable cations, bentonite can be divided into sodium bentonite (alkaline soil), calcium bentonite (alkaline soil) and natural bleaching clay (acid soil or acid clay).

The applications of bentonite

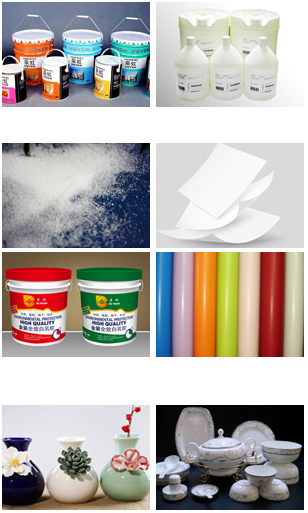

The bentonite can be ground and processed by the bentonite grinding mill into bentonite powder. Bentonite powder has diverse applications according to different types and specifications.

·Refined lithium bentonite

It is mainly used in various molding coatings and ceramic glaze coatings, as a suspending agent and thixotropic agent for base materials. Used in daily-use chemicals such as latex paints, as thixotropic agent for suspension emulsions and pastes, latex stabilizers, thickeners, and also used as sizing on fabrics.

·Refined sodium bentonite

1. In the mechanical molding industry, it can be used as molding sand and binder, which can avoid the sand inclusion and peeling phenomenon, reducing the rejection rate, ensuring the accuracy and degree of finish.

2. In the paper industry, it is used as a filler for paper to enhance the brightness.

3. Its strong bonding properties can be used for the production of white latex, floor glue, paste, etc.

4. Thanks to its stable suspending and thickening properties, it can effectively float the dispersed powder, and can be used as a thickening and anti-settling additive for water-based coatings.

5. It can be used as soda soil for drilling mud due to its excellent dispersibility and swelling properties, high pulping rate, low water loss, and colloidal properties and shear dilution ability.

·Ceramics bentonite

Bentonite powder can be added into the production of ceramics to increase the plasticity and strength of the embryo body or glaze, which can dramatically increases the lubricating effect and the suspension and stability. fine and smooth porcelain, excellent transmittance, anti-collision, and with certain mechanical strength.

·Highly effective activated carclazyte

1. Refining of animal and vegetable oils, is used for decolorization and purification, removing harmful pigments, phospholipids, saponin, gossypol, etc., from oil to make it to be high-grade edible oil.

2. In the petroleum industry, it is used for the decolorization and purification of petroleum, oil paraffin, wax oil, kerosene and other minerals, and petroleum cracking.

3. In the food industry, it is used as a clarifying agent for wine and sugar juice, stabilizing treatment for beer, saccharification treatment, and purification of sugar juice.

4. In chemical industry, it is used as catalyst, filler, desiccant, adsorbent, flocculant for wastewater treatment.

5. In national defense, medicine and health industries, it can be made into anti-drug, antidote. With the development of society and science, the applications of activated clay has greatly increased.

·Calcium-based bentonite

It is mainly used as binder in molding sand and asbestos insulation materials, and radioactive waste absorbent. Used as carrier, diluent, or pesticide in pesticides; and drilling mud washing fluid.

Model selection of bentonite grinding mill

Phase 1: Crushing the raw materials

Marble blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 2: Grinding

The crushed coarse marble are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine marble powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

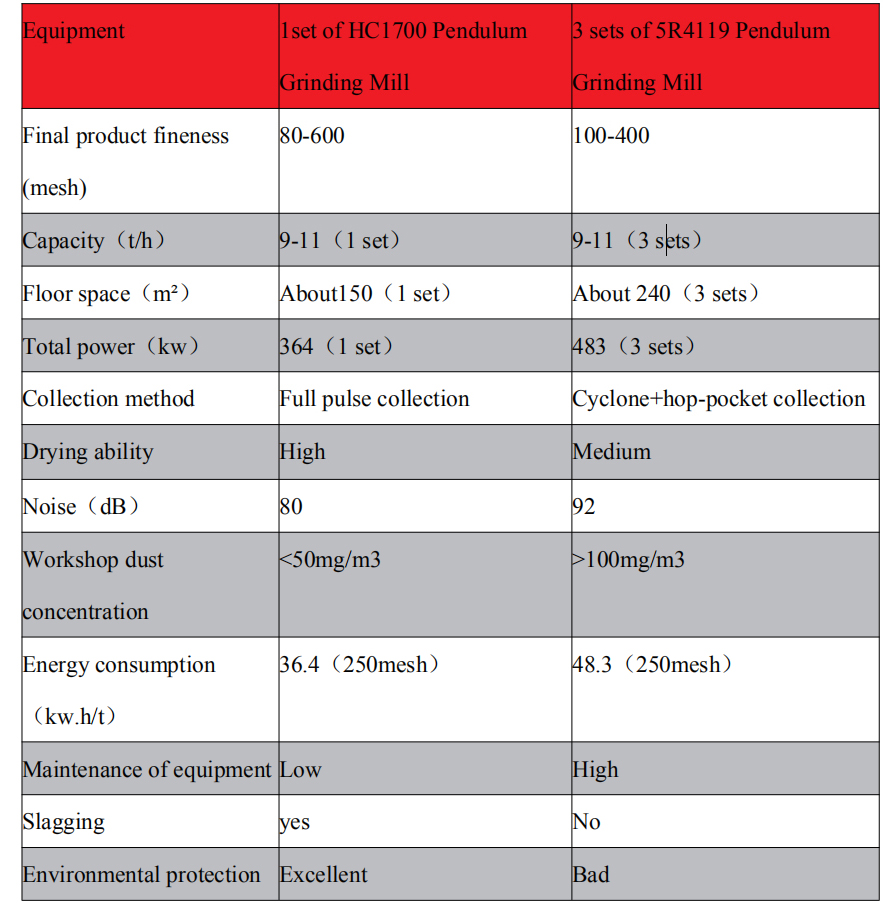

Bentonite powder milling case

Grinding material:bentonite

Fineness:325meshD90

Capacity:8-10t/h

Equipment configuration:1 set HC1300 Grinding Mill

Customer evaluation: The product yields of HC1300 is increased by up to 2 tons as compared with conventional 5R roller mills under the same production. With the features of lower specific energy consumption (measured in kWh/t of produced material), highly efficient dedusting, high power intensity, abrasion resistant designs, simple foundations low installation cost, the whole process of design, installation guide and debugging are free, we are very satisfied and trust Hcmilling (Guilin Hongcheng).