Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-12-05 16:32:42

What is potassium feldspar?

Potash feldspar is also known as orthoclase that belongs to monoclinic system with Mohs hardness of 6, is a water-insoluble potassium resource with high potassium content, wide distribution, and large reserves. Generally in in flesh red yellow, white, or other colors. With the features of low melting point (1150 ± 20 ℃), long time of fusing interval, high fusing viscosity, etc. In this paper we will discuss more about potash feldspar powder solution.

Applications of Potash Feldspar

Potash feldspar is widely used in ceramics blanks, ceramic glazes, glass, electric porcelain, abrasive materials, potassium fertilizer production, and other industries. Approximately 50-60% of potassium feldspar is used as raw materials for the glass industry, approximately 30% of potassium feldspar is used in the ceramic industry , and the rest is widely used in chemicals, glass fluxes, Ceramic body ingredients, ceramic glazes, enamel raw materials, abrasives, glass fibers, welding electrodes and other industries.

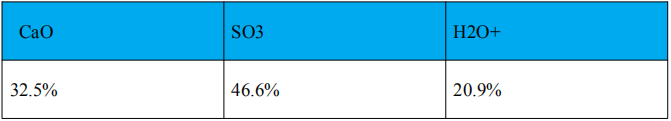

Analysis of Potassium Feldspar Raw Material Composition

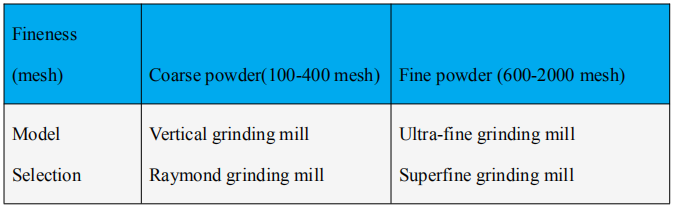

Potash Feldspar Grinding Mill Model Selection

Processes of Potassium Feldspar Grinding Milling

Phase 1: Crushing the raw materials

Potash Feldspar blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 2: Grinding

The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine Potash Feldspar powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

Analysis of different types of grinding mill

HLM Vertical Grinding Mill

Large-scale equipment, extremely high product yields, high degree spheroidization of final product, superior quality, high capital investment.

HLMX Superfine Vertical Grinding Mill

HLMX superfine vertical grinding mill is preferred to grind superfine powder above 600 mesh for large-scale production, or those who have high demand of spheroidization of final product.

It is an economic and efficient grinding mill that concentrate on grinding fineness above 600 mesh.

HC series Large-scale Pendulum Grinding Mill

Lower capital investment, high product yield, lower energy consumption. Disadvantages: relatively lower product yield on a single mill.

Potash Feldspar Milling Case

Grinding material: Potash feldspar

Fineness: 200 mesh D97

Product yield: 6-8t/h

Equipment configuration : 1 set of HC1700 Grinding Mill

Customer evaluation:

Hcmilling (Guilin Hongcheng)’s Potash feldspar Grinding Mill has advanced Classification System, highly efficient grinding, reliable equipment performance, precise oversize removal, simple foundations low installation cost, our product yield has been dramatically increased, it is worth to be recommended for Potash feldspar powder solution.