Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-12-06 11:32:38

What is kaolin?

Kaolin is a nature and common seen non-metallic clay mineral. Pure kaolin is white, fine, soft, and has good physical properties such as excellent plasticity, fire resistance, suspension, and adsorption. There are abundant kaolin resources all around the world that are widely distributed in China, the United States, the United Kingdom, Brazil, India, Bulgaria, Australia, Russia and other countries.

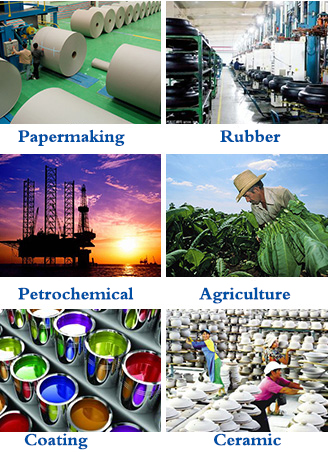

The applications of Kaolin

Kaolin plays an important role in the industries of rubber, plastics, refractories, petroleum refining, agriculture, and cutting-edge technologies in defense.

1. Papermaking industry:

Kaolin is used in papermaking to ensure an excellent covering performance and coating gloss performance. It can also increase the whiteness, opacity, smoothness and printability of the paper, which has greatly improved the paper quality.

2. Ceramic industry:

In ceramics industry, kaolin can be used to assist the formation of mullite and improves its chemical stability and sintering strength.

3. Petrochemical industry:

Kaolin can be used as a catalytic filler for petroleum cracking. Kaolin has high purity, which is conducive to produce the catalyst support.

4. Coating industry:

Kaolin can be filler and pigment substitute.

5. Rubber field:

Nanoscale kaolin can improve the elasticity, anti-buckling, dimensional stability, compressive deformation and other properties of rubber.

6. Agriculture:

Kaolin aqueous solution can be used in agricultural fields such as fruit trees, grains, and vegetables, which can greatly reduce production costs and pesticide residues in crops.

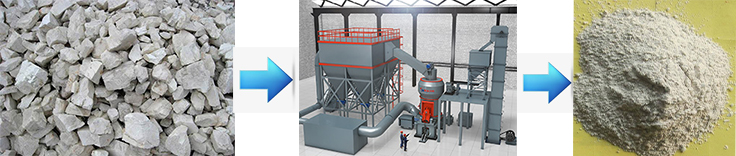

Kaolin Powder Milling Process

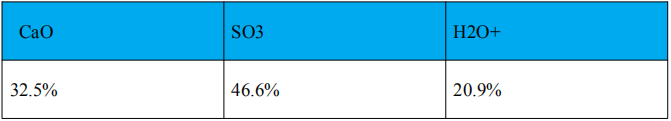

Analysis of Kaolin raw material composition table

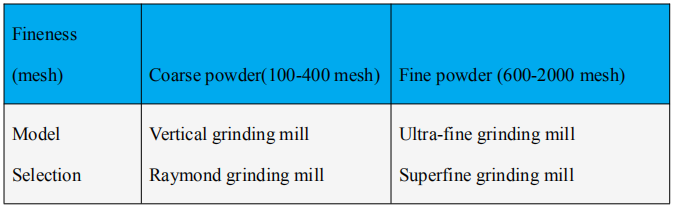

Model selection of kaolin grinding mill

Potash Feldspar blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 1: Crushing the raw materials

Phase 2: Grinding

The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine Potash Feldspar powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

Analysis of different types of grinding mill

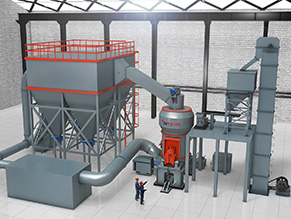

HLM Vertical Grinding Mill

Large-scale equipment, extremely high product yields, high degree spheroidization of final product, superior quality, high reliability. High capital investment.

HLMX Superfine Vertical Grinding Mill

HLMX superfine vertical grinding mill is preferred to grind fineness above 1250 mesh, and can produce 3μm fineness if equipped with the multi-level classification system. Efficient grinding, high degree of spheroidization. Higher capital investment than ultra-fine grinding mill.

HCH Ultra-fine Grinding Mill

Lower capital investment and energy consumption, it is an economic and efficient grinding mill, but lower yield on a single mill. Multiple mills will be needed for large-scale production.

Lower capital investment, high product throughput, lower energy consumption and noise, high reliability. Multiple mills will be needed for large-scale production.

Kaolin Powder Milling Case

Grinding material: kaolin

Fineness: 200 mesh D97

Product yield: 6-8t/h

Equipment configuration : 1 set of HC1700 Grinding Mill

Customer evaluation: we have known Hcmilling (Guilin Hongcheng) for many years, and it turns out we made the wise option to cooperate with it, the throughput of HC1700 Grinding Mill has increased 30%-40% than conventional grinding mill,our grinding efficiency and throughput has been increased dramatically, and the final product has a very strong market competitiveness, we are also very satisfied about its after sale service and would highly recommend it to you.