Welcome to Guilin HCM Machinery Official WebSite!

Release date: 2019-12-11 10:44:39

What is gypsum?

Gypsum is a monoclinic mineral that mainly composed of calcium sulfate (CaSO4). Gypsum can generally refer to two kinds of minerals, raw gypsum and anhydrite. Raw gypsum is also called dihydrate gypsum, hydrogypsum or soft gypsum, which is usually dense or threadiness with Mohs hardness of 2, anhydrite is anhydrous calcium sulfate, usually dense or granular in white, off-white, glass gloss, with Mohs hardness of 3 ~ 3.5. we will discuss about more about gypsum powder solution in this paper.

The applications of gypsum

Gypsum has been widely applied in various industries such as construction, agriculture, thermal power plants, chemical industry, etc.

1.Construction and building material industries: Stucco gypsum can be obtained when gypsum is calcined to 170 ° C, and can be used to coat ceilings, wood boards, etc . Gypsum can be used as cement and cementitious materials, and be used as filler in plastic, rubber, coating, asphalt, linoleum and other industries. It can also be used as a main raw material for coagulation and expansion agents, anti-cracking agents, and self-leveling mortar.

2.Chemical industry: Gypsum can be used to produce sulfuric acid as well as lightweight cement; it can produce ammonium sulfate and light calcium carbonate.

3.Agriculture: Gypsum can be used to improve soil and adjust pH; it can be used as a calcium and sulfur compound mineral fertilizer in the cultivation of edible fungi; and as a compound mineral feed additive in poultry and livestock death cells.

4.Thermal power plant industry: it’s significant to choose a good desulfurizer to absorb sulfur dioxide, gypsum is a high-efficiency desulfurizer due to its fine particle size has a favorable absorption function, and the more efficiently and quickly the sulfur can be desulfurized and purified.

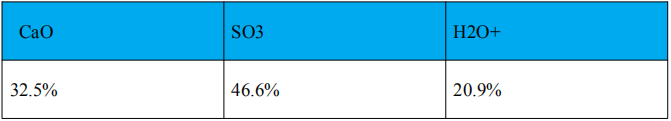

Analysis of raw material components of gypsum

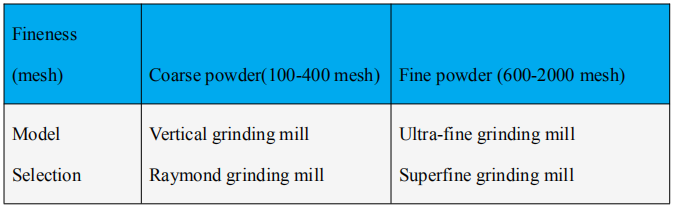

Model Selection of Gypsum Grinding Mill

Gypsum Powder Milling Process

Phase 1: Crushing the raw materials

Potash Feldspar blocks are crushed by the crusher to the size of 15mm-50mm and into grinding mill.

Phase 2: Grinding

The crushed coarse Potash Feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber by the feeder for grinding.

Phase 3: Classification

The ground material is classified by the classification system, and the unqualified powder will returned to the main mill to be reground.

Phase 4: Collection of finished products

The qualified fine Potash Feldspar powder enters the dust collector through the pipeline along with the airflow for separation and collection. The collected finished powder is sent from the conveying device to the finished product bin through the discharge port, and then packed by a powder tanker or automatic packer.

Analysis of different types of grinding mill

Large-scale equipment, extremely high product yields, high degree spheroidization of final product, superior quality, high reliability. High capital investment.

HLMX Superfine Vertical Grinding Mill

HLMX superfine vertical grinding mill is preferred to grind fineness above 1250 mesh, and can produce 3μm fineness if equipped with the multi-level classification system. Efficient grinding, high degree of spheroidization. Higher capital investment than ultra-fine grinding mill.

HCH Ultra-fine Grinding Mill

Lower capital investment and energy consumption, it is an economic and efficient grinding mill, but lower yield on a single mill. Multiple mills will be needed for large-scale production.

HC Super Large Grinding Mill

Lower capital investment, high product throughput, lower energy consumption and noise, high reliability. Multiple mills will be needed for large-scale production.

Gypsum Powder Milling Case

Grinding material: Gypsum

Fineness: 325 mesh D97

Product yield: 8-10 t/h

Equipment configuration : 1 set of HC1300 Grinding Mill

Customer evaluation: Hcmilling (Guilin Hongcheng) vertical grinding mill requires a simple and small foundation, less floor space is required, significantly reducing initial costs. It is an excellent grinding solution because of the ease of operation and maintenance, energy efficiency and product quality, further more, it has an ability to dry, grind and separate within a single unit. And we are very satisfied with Hcmilling’s excellent after sale service.