Bauxite is also known as alumina bauxite, the main component is alumina oxide which is hydrated alumina containing impurities, is an earthy mineral; white or gray, shows in brownish yellow or pink color because of iron contained. Density is 3.9~4g/cm3, hardness 1-3, opaque and brittle; insoluble in water, soluble in sulfuric acid and sodium hydroxide solution.

Bauxite is rich in resources, needed for many industries; therefore, it is a very popular non-metallic material, and the reason why it has been generally welcomed, mainly because it is very promising in the industrial field.

1. Aluminum industry. Bauxite used in national defense, aerospace, automotive, electrical, chemical and other daily necessities industries.

2. Casting. Calcined bauxite is processed into a fine powder for casting after the mould and used in military, aerospace, communications, instrumentation, machinery and medical equipment sectors.

3. For refractory products. High calcined bauxite refractoriness can reach up to 1780 鈩? chemical stability, good physical properties.

4. Aluminosilicate refractory fibers. With several advantages such as light weight, high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity and resistance to mechanical vibration and so on. Can be used in iron and steel, nonferrous metallurgy, electronics, petroleum, chemical, aerospace, nuclear, national defense and other industries.

5. Raw material of magnesia and bauxite, added with appropriate binder, can be used for casting overall cylinder liner of molten steel ladle with very good results.

6. The manufacture of bauxite cement, abrasive materials, various compounds can be made of aluminum bauxite in ceramic industry and the chemical industry.

Bauxite ingredient analysis sheet

| Al2O3、SiO2、Fe2O3、TiO2、H2O+as the main component | S、CaO、MgO、K2O、Na2O、CO2、MnO2 | Ga、Ge、Nb、Ta、TR、Co、Zr、V、P、Cr、Ni etc |

|---|---|---|

| >95% | Minor component | Trace elements |

Bauxite powder making model selection program

| Specification | Fine powder processing(80-400mesh) | Ultrafine powder deep processing(600-2000mesh) |

|---|---|---|

| Equipment selection program | Vertical grinding mill and raymond grinding mill | |

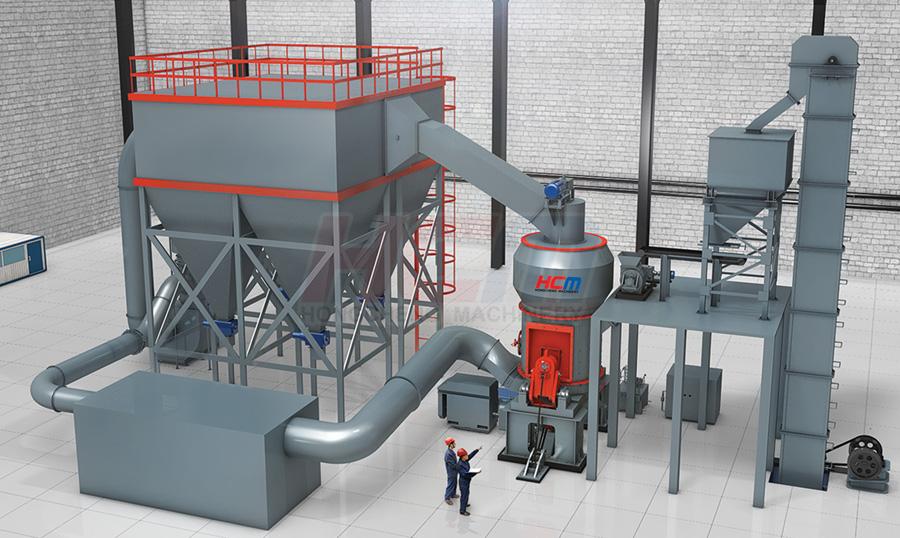

1. HC Series Grinding Mill: low investment cost, high capacity, low energy consumption, steady operation, low noise. Disadvantages: lower single capacity, not large-scale equipment.

2. HLM Vertical Mill: large-scale equipment, high capacity, steady operation. Disadvantages: higher investment cost.

Phrase one: raw material crushing:

Bauxite blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding:

Bauxite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Ground material will be classified; coarse powder will fall back to the main mill to be ground again.

Phrase four: production collecting:

Qualified powder will flow with the air and be collected in the collector, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

We offer full set of calcite powder processing solution to convoy your calcite powder project!

Learn more about powder processing integration service

Some bauxite processing enterprise

Material: Bauxite

Fineness: 325mesh D97

Capacity: 8-10t/h

Configuration: 1 set of HLM2400

Guilin Hong Cheng has strong strength, solid foundation in the field of production of milling, is expert in milling machine R&D and manufacturing field. Through repeated comparison and multiple market surveys, we decided to choose Hong Cheng bauxite grinding mill (HLM2400 vertical mill), Guilin Hong Cheng bauxite mill production equipment is high quality, stable performance, excellent quality, can meet the production needs of bauxite processing, and more importantly, Hong Cheng has a strong professional and technical, high-quality after-sale maintenance engineer team, assisted us for plant debugging, installation of Bauxite vertical mill during supply, made great contribution for the officially operation of our bauxite powder processing.