Marble and calcite are all normal non-metallic materials, can be process into different fineness of powder which called as heavy calcium carbonate after grinded by grinding mill or other mine equipment, can be widely used in papermaking, plastic, rubber, household chemicals, cosmetics, building materials, paints, pharmaceuticals, food and other industries. Marble is divided into coarse concentrate and fine-grained ore, the same tone of biased plainer phase, plenty of reserves in domestic, market usage amount is relatively large, the amount of calcium content is about 96% -98%.

Its use is more widespread in paint, paper, chemicals, fertilizers, construction, food and other areas of high-value applications.

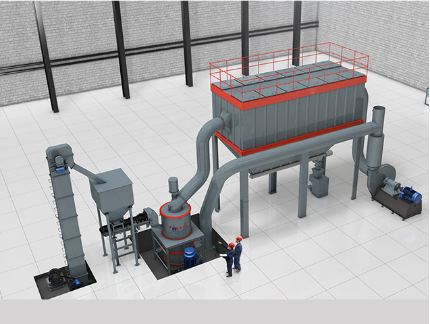

HCH ultra-fine mill, can be said professional equipment for HCC grinding, advanced technology of ring roller mill is widely used in talc, calcite, calcium carbonate, dolomite, feldspar, bentonite, kaolin, graphite and other non-metallic materials;

With high chemical purity, inert, difficult for chemical reaction, thermal stability, high brightness, low oil absorption, low refractive index, soft, dry, non-toxic, tasteless and odorless, it is widely used in paper, plastic, plastic film, chemical fiber, rubber, adhesives, sealants, household chemicals, cosmetics, building materials, paints, pints, inks, putty, sealing wax, putty, carpet packaging, pharmaceuticals, food (such as chewing gum, chocolate), feed field and the like, having distinctive advantages as follow: increase the volume of products, reduce costs, improve the processing performance (such as adjusting the viscosity, rheological properties, curing properties), improved dimensional stability, a reinforcing or semi-reinforcing, improved printing performance, improved physical properties (such as heat resistance, matting properties, abrasion resistance, flame resistance, whiteness, glossiness) and so on. Therefore, heavy calcium carbonate has become increasingly important in the production of human life.

Marble ingredient analysis sheet

| CaCO3 | MeCO3、 CaO、MnO、SiO2 and so on |

| 50% | 50% |

Marble powder making equipment selection program

| Specification (mesh) | Fine powder processing(20 mesh-400 mesh) | Deep processing of ultrafine powder(600 mesh-2000 mesh) |

| Equipment selection program | Vertical grinding mill or pendulum grinding mill | Ultrafine grinding roller mill or ultrafine vertical mill |

Note: Select main mill according to capacity and fineness.

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3, HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4, HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Phrase one: raw material crushing

Bentonite blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed Marble material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Ground marble powder will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

We offer full set of calcite powder processing solution to convoy your calcite powder project!

Learn more about powder processing integration service

Some marble processing enterprise

Material: Marble

Fineness: 800mesh D97

Capacity: 6-8t/h

Configuration: 2 sets of HCH1395

Producing powder of the same fineness, HC1300 have 2 tons higher capacity than traditional 5R mill, which lower the energy consumption. The whole system operates under full automatic control, it only need our worker to do some simple operates in the control room, which saves up labor cost. Lower cost of operating will bring more competitiveness to our production. More over, all the designing, installing and testing of the project are all free, we are very satisfied about it.