Manganese has a wide distribution in nature, almost all kinds of minerals and silicate rocks contain manganese. It has been known that there are about 150 kinds of manganese minerals, among them, manganese oxide ore and manganese carbonate ore are important industrial material, have the highest economic value. The majority component of manganese oxide ore are MnO2, MnO3 and Mn3O4, the most important are pyrolusite and psilomelane. Chemical component of pyrolusite is MnO2, manganese content can reach 63.2%, usually contents water, SiO2, Fe2O3 and psilomelane. Hardness of the ore will be different because of crystalline degree, the hardness of phanerocrystalline will be 5-6, cryptocrystalline and massive aggregation will be 1-2. Density: 4.7-5.0g/cm3. Chemical component of psilomelane is hydrous manganese oxide, manganese content about 45%-60%, usually contents Fe, Ca, Cu, Si and other impurities. Hardness:4-6; specific gravity: 4.71g/cm³. India is the top producing area of manganese, other major producing areas are China, North America, Russia, South Africa, Australia, Gabon, etc.

Manganese product including metallurgy manganese, manganese carbonate powder (important material of manganese refining), manganese dioxide powder, etc. Metallurgy, light industry and chemical industry have different requirement of manganese product.

| Rate | MnO2 Content (≥%) | Remark |

|---|---|---|

| Top | 80 | Product impurity content should be negotiated according to requirement; Fineness should be 100 mesh D95, the supplier and buyer should negotiate for different requirement. Product moisture should be less than 3%, hygroscopic moisture based on the inspection result when packing (if the material is Soot pyrolusite with high water absorption, the product moisture can be more than 3%); Product should not be polluted by exogenous impurity. |

| 1st | 75 | |

| 2nd | 70 | |

| 3rd | 65 | |

| 4th | 60 | |

| 5th | 55 | |

| 6th | 50 |

| 200 mesh D80-90 | Raymond mill | Vertical mill |

|---|---|---|

| HC1700 & HC2000 Large Grinding Mill can realize low cost and high out put | HLM1700 and other vertical mills have obvious competitive power in large-scale producing |

HC Series grinding Mill capacity/energy consumption table

| Model | HC1300 | HC1700 | HC2000 |

|---|---|---|---|

| Capacity (t/h) | 3-5 | 8-12 | 16-24 |

| Energy consumption (kwh/t) | 39-50 | 23-35 | 22-34 |

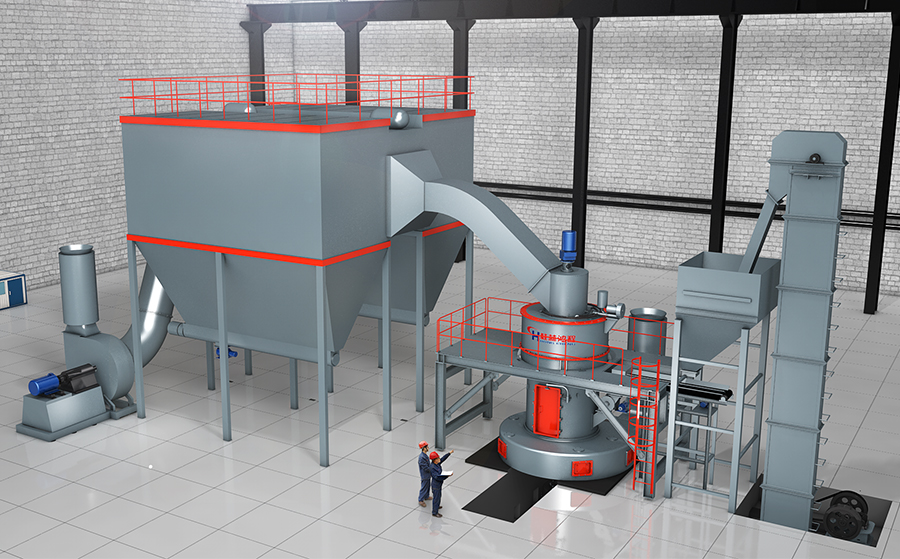

HLM Vertical Manganese Mill technical diagram (manganese industry)

| Model | HLM1700MK | HLM2200MK | HLM2400MK | HLM2800MK | HLM3400MK |

|---|---|---|---|---|---|

| Capacity (t/h) | 20-25 | 35-42 | 42-52 | 70-82 | 100-120 |

| Material moisture | ≤15% | ≤15% | ≤15% | ≤15% | ≤15% |

| Product fineness | 10 mesh (150μm) D90 | ||||

| Product moisture | ≤3% | ≤3% | ≤3% | ≤3% | ≤3% |

| Motor power (kw) | 400 | 630/710 | 710/800 | 1120/1250 | 1800/2000 |

1. Raymond mill: low investment cost, high capacity, low energy consumption, stable operation, low noise;

2. Vertical mill (HLM Manganese Vertical Mill): high capacity, large-scale production, easy maintenance, high automatic level. Higher investment cost than Raymond mill.

Phase one: raw material crushing Manganese blocks will be crushed to 15mm-50mm fineness by crusher.

Phase two: grinding Crushed manganese material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

We offer full set of calcite powder processing solution to convoy your calcite powder project!

Learn more about powder processing integration service

.jpg)

Some manganese ore processing plant

Raw material: manganese carbonate

Finished fineness: 90-100 mesh

Capacity: 8-10t/h

Equipment: 6 sets of HC1700

The customer enterprise locates near rich manganese mines. The customer decided to grind the manganese for better application. After site investment, the customer purchased HC1700 Grinding Mill, this is the 51st equipment in Guizhou area. The new Mineral Powder Mill start operation in early 2015.